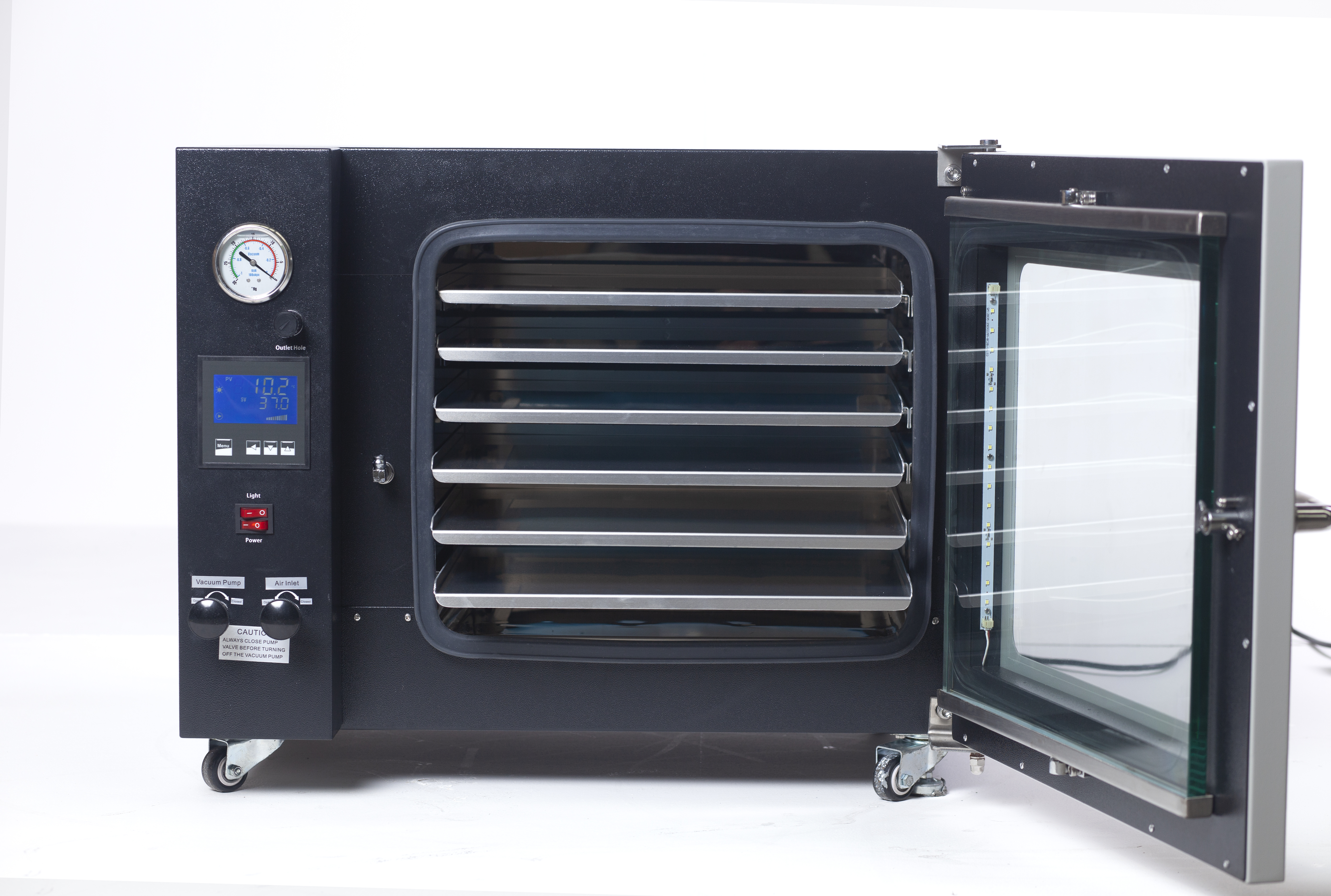

For the easy and efficient degassing and purging light hydrocarbon solvents, look no further than our purpose-built ECO vacuum oven with LED display.

Using cold-boiling, this oven applies gentle heat under reduced pressure to expedite solvent degassing while preserving colour, aroma, and overall quality. The ECO vacuum oven has five (5) spacious shelves with optimal heat distribution and perfect uniformity across each shelf surface. It’s low consumption, high-throughput, and reliable, so you’ll spend less money and time getting the job done.

|

||

| Optimal heat distribution across entire interior chamber. (0.9cf model shown) |

PERFORMANCE CAPABILITIES

At 420PMUK, we make every effort to provide oven performance capabilities in a standardized format. We’re not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers.

- Temperature Range: Room to 212F;

- Temperature Stability: ±1.0°

- Temperature Uniformity: within 7% of the temperature setpoint.

- Heat-Up Time: 45 minutes to preheat. Optimal saturation reached in 120 minutes, over 30 minutes faster than competitors.

- Ultimate Vacuum: <500 µmHg / mTorr / micron

- Time to Vacuum: 4 minutes to 29″Hg using our VE Series 4cfm Dual Stage Vacuum Pump.

- Vacuum Hold: guaranteed to lose less than 1″Hg (25.4 torr) in 24 hours.

SPECIFICATIONS

| Electrical | Voltage | 220V |

| Frequency | 50 Hz | |

| Power | 800W | |

| Current | 6.7A | |

| Plug | IEC C13 (unit ships with detachable NEMA 5-15p cable) | |

| Internal Chamber | Heating | 4 Wall Heating (left, right, top, bottom) |

| Chamber Material | Stainless Steel | |

| Dimensions (LxWxH) | 14.5″ x 16.5″ x 13.75″ | |

| Vacuum Gauge | Style | Analog vacuum gauge with dual units |

| Range (units) | -30 to 0 (inHg) / -1 to 0 (bar) | |

| Shelving | Ships With | 5 Slide-in Shelves |

| Maximum | 8 Slide-in Shelves | |

| Shelf Dimensions (LxW) | 15.5″ x 13.75″ | |

| Shelf Capacity | 213 in2 | |

| Max Shelf Capacity | 2344 in2 / 16.3 ft2 | |

| Door | Seal | Silicone on Tempered Glass |

| Window Dimensions (LxH) | 11.75″ x 11″ | |

| Lights | 2 strips of LEDs provide clear, bright view of interior | |

| Handle | Shock-resistant ABS plastic with metal parts | |

| Exterior | Dimensions (LxWxH) | 28″ x 22″ x 21″ |

| Weight | 205 lbs | |

| Safety | Electrical | Fused for protection |

| Thermal | Automatic overtemperature shutoff | |

| Compliance | CE | CE Listing Recognized |

| ISO | ISO 9001:2008 / 13485:2003 | |

| IEC | IEC68-2-3 | |

| Connections | Vacuum Inlet | 1/4″ Flare JIC |

| Atmospheric Release | Quick-release dial | |

| Contains | Ships With | 1/4″ vacuum hose, spare fuses, wrenches |

| User Manual | Included | |

| Vacuum Pump | Sold Separately. | |

| Recommended Pump | VE Series 4cfm Dual Stage Vacuum Pump | |

| Warranty | 2 Years |

CAPACITY AND THROUGHPUT PLANNING

Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity:

- Size = Extraction Batch Size (lbs)

- Number = Runs per 24h Period

- Purge = Your desired purging duration (hours)

Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122

Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18

Disclaimer

420PMUK sells only equipment manufactured to the highest standards and quality is assured in all our products

However, due to the chemical properties of butane there remains an element of risk in the operation. It is necessary for the users of such equipment to be aware of these risks and familiarise themselves with the instructions regardless of their level of experience. Due to the volatile properties of butane, there is an ever-present risk of danger in its use, and 420PMUK cannot be held responsible for any bodily harm or damage to property that may result from its usage with any of our equipment.

420PMUK urges all users to take necessary precautions before using our products, especially when the operation requires the use of dangerous substances.

420PMUK does not advocate the use of such equipment for the processing or production of any substances covered by the Misuse of Drugs Act 1971 or any subsequent relevant legislation. Products sold by distributors are sold on the understanding that they shall be used for legitimate purposes only, and are obliged to clarify that the usage of our products for any illegal purposes may result in police involvement and any appropriate penalties under law.